Triple-junction metal wrap through solar cells tested in space

German researchers from the University of Stuttgartt and Azur Space Solar Power, the cell manufacturing subsidiary of Canada-based high-purity materials provider 5N Plus, conceived a miniaturized solar cell experiment (SCE) for nanosatellites.

The SCE was used in low earth orbit to measure the performance of novel triple-junction metal wrap-through (MWT) solar cells being developed by Azur Space for the new space sector alongside quadruple-junction solar cells.

The team’s novel instrumentation successfully sampled more than 5,000 IV-curves, cell temperatures, sun error angles, and total ionizing dose (TID) measurements, as described in “Design and first results of the solar cell experiment on EIVE,” published in Acta Astronautica.

The data gathered in orbit was in turn used to validate the sophisticated temperature and solar simulator characterization tools in the lab on the ground.

“Within the last decade some organizations and universities have launched solar cell experiments on CubeSats, however, with mixed results due to the very constraining nature of such miniaturized satellite platforms,” Markus T. Koller, the research’s corresponding author told pv magazine. “We have shown that well-designed measurement electronics and a reliable satellite platform will enable proper solar cell characterization in the real space environment.”

The experiment is ongoing, with the number of IV curves measured reaching 6,680 as of early February 2025, according to Koller.

The nanosatellite platform in this case was the exploratory in-orbit verification of an E-band link (EIVE), which was developed by a German consortium comprising several research institutes and industrial partners. It is a low earth orbit (LEO) satellite.

“From the technological viewpoint, the study has shown that the metal-wrap-through technology is valid for use in space and does not pose any drawbacks for the solar power generation in space,” said Koller.

On the experiment side, it has proven that solar cell experimentation on nanosatellite platforms with “high mass, size and power constraints are capable of delivering adequate solar cell characterization results that stand up to the sophisticated and bulky space solar simulators on Earth,” according to Koller.

“If both results match well, it means that both approaches are adequate to test new solar technologies for space applications,” he said.

For the experimental setup, the researchers examined earlier solar cell space experiments, deciding to use of electronic load circuit and radiation-sensitive field-effect transistor (RadFET) due to power, mass, and size constraints, despite challenges that “can introduce artefacts in IV-curves,” if not mitigated.

The load circuit was based on a proportional-integral (PI) controller at the gate of a low-transconductance SI3460BDV n-channel metal-oxide-semiconductor field-effect transistor (MOSFET), and current feedback loop, combined with digital point filtering that enhanced the point distribution on the IV-curves.

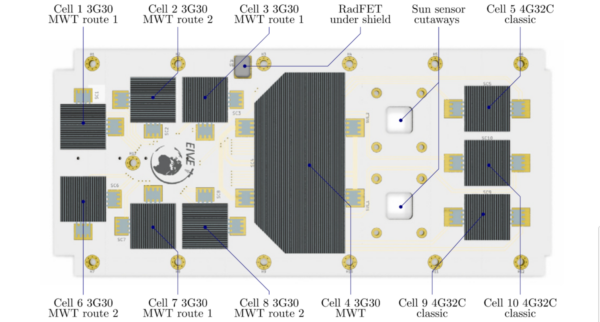

Image: University of Stuttgart

The test board included nine 2 × 2 cm2 cells and one that measured 4 × 8 cm2. The cells were either Azur Space's 3G30 triple-junction cells or 4G32 quadruple-junction models.

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd