Solar manufacturing slows in bid to balance supply and demand

From pv magazine print edition 12/24

Economic headwinds and changing policy have seen the global solar market slow during the second half of 2024. Discussion continues to focus on how to alleviate PV oversupply.

InfoLink has conservatively predicted 492 GW to 568 GW of solar demand in 2025, but it could be even weaker, possibly falling below the 469 GW to 533 GW expected of 2024.

Older production lines have begun to be phased out since July 2024 and new factories have adjusted and even postponed production, but negative profit margins have occurred, and the pace of profit recovery remains slow.

The Chinese solar industry has tried to address oversupply. Chinese industry associations have started actively coordinating prices and calling for self-regulation among manufacturers based on cost guidance. Regulations stipulating higher product quality standards are also possible. Such supply-side reforms, however, will take time to have effect and InfoLink will monitor developments.

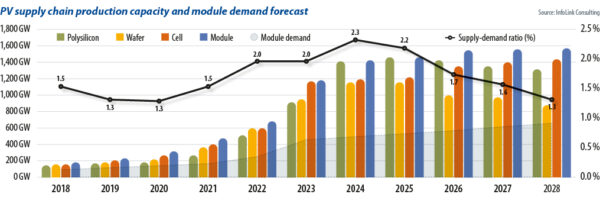

Supply chainWafer makers, the smallest segment of the solar supply chain, could produce 2.3 times more product than demand. Comparing production capacity across all of the supply chain with module demand shows the gap is closing but the pace of capacity shutdowns has been slow. Continuing oversupply has caused spot prices in some parts of the supply chain to fall below cash cost levels, resulting in a situation where prices are inverted.

The second half of 2024 is expected to see accelerated capacity elimination and phase-out across various segments. This will include capacities among new-entrant companies and those of tier 2 and tier 3 manufacturers.

Polysilicon production is highly consolidated and manufacturers are studying peers for fear of losing market share.

It is expected that capacity clearing in the polysilicon segment will not be completed quickly. On the ground, some tier 3 companies began shutting down in the third quarter of 2024. Tier 2 producers are struggling and new entrants are caught in a difficult position. Meanwhile, leading companies are also facing severe profitability pressures and the challenge of cash flow losses across the board. These factors are expected to accelerate larger-scale production capacity exits in 2025.

In the midstream segment of the supply chain, manufacturing capacity growth rate for the wafer segment has noticeably slowed as companies try to differentiate products by enhancing quality and changing product sizes. The output of positively doped, p-type wafers continues to decline, with fewer manufacturers producing 182 mm and 210 mm wafers. Some tier 2 and tier 3 manufacturers may face operational crises. As existing capacities are phased out more rapidly, gross profit margins are expected to return to healthier levels in 2025 and 2026.

Cell and moduleCustomized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd