Shift to 2 kV voltage in solar projects tipped to gain traction

From pv magazine print edition 12/24

The rationale for moving from 1.5 kV voltage to 2 kV in solar projects is grounded in electrical principles, particularly the relationship between electric power (P), current (I), and voltage (V) – expressed as P=IV. By increasing voltage while keeping current constant, power output can be increased without additional losses. This transition is expected to yield a 0.5% to 0.8% increase in energy yield for PV sites.

Higher voltages accommodate longer module strings. A 1.5 kV system can accommodate 33 modules rated at 45 V of direct current, while a 2 kV system can fit 44 modules – representing a 33% increase in power capacity. Longer string length means fewer strings. This helps decrease electrical balance of system expenditure, including costs for combiner boxes, connectors, and cabling, by 10% to 15%. The number of inverters needed should also decrease, as higher voltages accommodate more power-dense electronics.

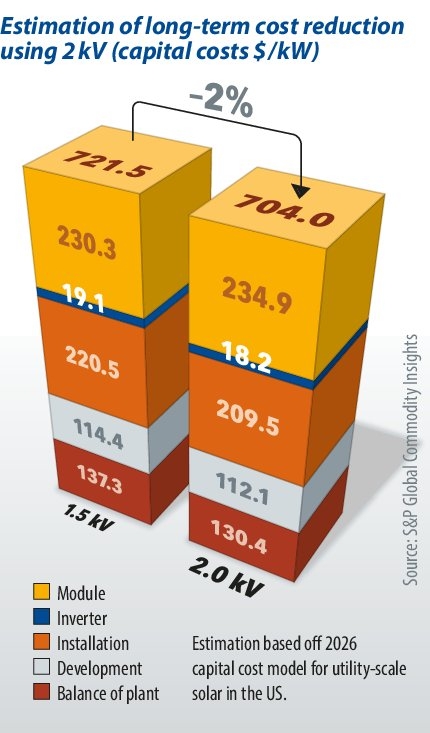

While 2 kV inverters cost more because of a smaller scale of manufacturing of some components and increased testing requirements – the long-term outlook is still positive. Switching to 2 kV will make inverters more power dense, saving on casings, fuses, and other components. Fewer solar project components should reduce labor costs and mean lower operation and maintenance (O&M) expenses. That could mean 1% to 2% lower capital costs, eventually, plus higher energy yield.

Key challengesSeveral challenges must be addressed before widespread adoption can occur. The primary bottleneck is the availability of 2 kV inverters as numerous technical challenges must be solved. Currently, components capable of handling 2 kV are limited and inverter manufacturers have to contend with issues related to combiner boxes, external insulation, fuses, and switches. A substantial amount of hardware and software testing must be completed to ensure the reliability and safe operability of 2 kV inverters on the grid. There are also greater challenges related to adopting 2 kV for utility-scale string inverters than there are for central inverters, due to the former’s raised power density. This may slightly delay the adoption of 2 kV string inverters, compared to central devices.

Limited availability of standards is another significant barrier hindering the development and adoption of 2 kV products. Recently, JinkoSolar Holding Co. Ltd. became the first solar module company to receive certification from UL Solutions Inc. for its 2 kV modules. However, it will take time for fully formed certification processes to emerge and even longer for manufacturers to align their products with these standards. Convincing developers to invest in 2 kV projects poses another challenge, as these new sites will be inherently riskier than standard 1.5 kV projects, with higher costs and a smaller selection of suppliers.

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd