Reden Solar inaugurates 200 MW solar module production line in France

From pv magazine France

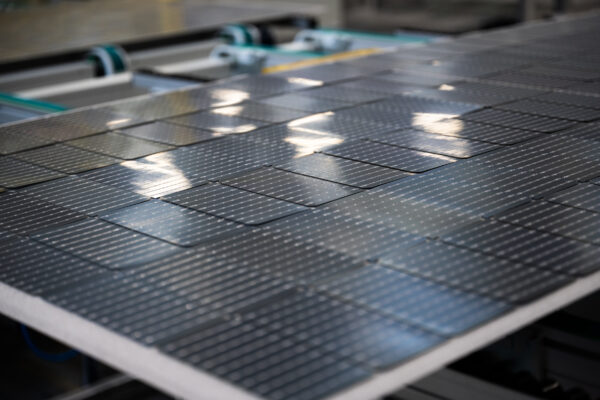

Reden Solar has opened a 200 MW solar module production line at its factory in Roquefort, Lot-et-Garonne, Nouvelle-Aquitaine, southwestern France.

The new line replaces a 65 MW production line that was installed 15 years ago, which had become outdated. The new line accommodates advancements such as 166 mm half-cells and 10 to 16 busbar connection points, replacing the earlier 72-cell modules with five busbars, said Tony Proutier, operations director at Reden Solar.

The company invested €4 million ($4.2 million) in the new equipment. Designed by Spanish manufacturer Mondragon, the modular line includes recustomized machinery from Eastern countries, particularly for cell welding. About 10 employees are needed to work on the line, producing up to 300,000 panels per year.

The factory manufactures mono passivated emitter and rear cell (PERC) panels with over 21.7% efficiency, rigorously tested for performance. The low-carbon-certified panels come in four ranges, from 405 W to 545 W, tailored for various applications like power plants, shade houses, and agrivoltaic systems.

Reden Solar Chairman and CEO Frank Demaille said that the company may eventually consider tunnel oxide passivated contact (TOPCon) technology.

“Our new production line will be able to adapt to it,” he told pv magazine France. “But TOPCon is only in its early stages, so it is better for us to have some perspective for its production.”

While the cells are manufactured in Asia, the copper comes from France and Belgium. The glass is from Austria and the EVA manufacturer is German.

“We are not passive when we buy panels or their components,” said Proutier. “We choose our raw materials to be transformed, by defining quality criteria with our partners and by carrying out on-site checks upstream. This is particularly the case for diodes, these small boxes that equip the modules and which are crucial for ensuring good connectivity.”

With Chinese solar panel prices falling, Reden Solar faces questions about the viability of producing its costlier modules in France.

“The additional cost is 50% to 70%, but the ‘panel' part of a solar power plant only accounts for one-quarter of the total price,” said Demaille.

The additional cost of using French-made panels – ranging from 15% to 25% depending on the power plant type – is always manageable. Producing its own panels gives Reden Solar a key advantage as an energy producer: full control of the PV value chain.

“It is a differentiating factor, which ensures a certain independence from large manufacturers,” said Demaille. “It also allows us to be in a stronger position when it comes to negotiating with our Chinese suppliers because we know their business in detail.”

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd