Progress on standardized tests, protocols for vehicle-integrated photovoltaics

Researchers from the University of Miyazaki in Japan have published a report about progress on reproducible tests and protocols that address the challenges of measuring the performance of curved vehicle-integrated photovoltaic (VIPV) modules.

In the study “Testing and rating of vehicle-integrated photovoltaics: Scientific background,” published in Solar Energy Materials and Solar Cells, the research team said its work addressed the unique aspects of VIPV modules, such as curvature, and irradiation impact caused by shading, partial-shading, dynamic shading, and uneven terrain conditions.

“The standard calculation for PV systems often relies on simplified assumptions, such as the absence of shadows, flat terrain, static installations, and uniform solar irradiance,” co-corresponding author, Kenji Araki, told pv magazine. “However, these assumptions do not accurately reflect real-world conditions. It is essential to consider actual imperfections, including the presence of shadows, uneven terrain, movable PV systems, and non-uniform solar irradiance. Although these factors are not commonly discussed, they significantly affect the performance of PV systems in practice.”

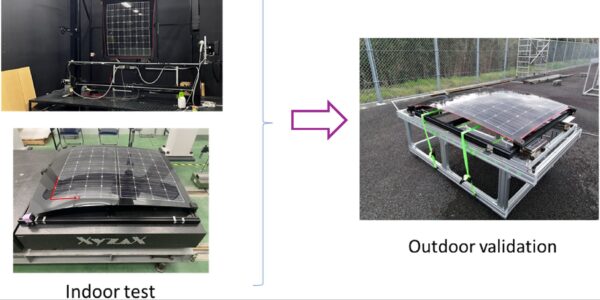

The team carried out initial testing of new protocols and validation at geographically diverse laboratories and research institutes, as well as solar simulator testing applying agreed protocols using the same calibration data, as well as blind tests. For round-robin tests, Nanjing AGG Energy, China, provided glass-covered rigid modules, including four levels of the radius of curvatures.

The group noted at least eight key differences to be addressed to achieve accurate models and measurements for VIPV products. For example, using a local coordinate system that includes 3D rotation, capturing the shading zones for vehicle doors, hood, bumper, and rear windscreen.

Vector computations based on a shading matrix are required, rather than shading ratio or angle. Tensor forms, 4-Tensor, are used for the angular response to the incident light, instead of the Lambartian curve, and rather than cosine loss by angles of the PV panel, differential geometry description using vector expression of a unit element is used, noted the researchers.

Some of the differences were summarized by Araki. “In the new model, a shading matrix accounts for non-uniform shading on the hemispheric sky. “In contrast, the classic analysis relies on a scalar shading ratio,” he explained, adding that the new method considers solar cells with curved surfaces and analyzes them using principles of differential geometry, “unlike the classic calculation, which assumes solar cells have a flat surface.”

Furthermore, the new model uses ray tracing “performed in vector form” instead of using a cosine approach, and rather than representing the angular response and incident angle modification (IAM) as curves based on the incident angle, “the new calculation depicts these as four tensors.”

Looking ahead, the researchers plan to develop a “fuel-saving estimation tool” for trucks and buses with PV panels. The validation based on monitoring 130 trucks, so far, is ongoing, according to Araki. In addition, there are other projects planned to address challenges in testing modules developed for agrivoltaics, building integrated PV, as well as alpine PV and aircraft-integrated PV, such as high-altitude pseudo satellites (HAPS).

The research work is the result of the collective contribution of members of the IEC TC82 PT600 initiative that aims to establish standards for VIPV systems.

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd