New fire safety testing procedure for PV systems deployed in flat roofs

ZAG researchers have designed and published a novel fire safety testing procedure (TP) for flat rooftops with PV modules. While most European and national testing focuses on material and product testing, this TP is novel because it includes all elements of the roof.

“We hope that this release can fast-track the process of establishing a harmonized fire test method for PV systems on flat roofs,” Grunde Jomaas, the head of ZAG's Department of Fire-Safe Sustainable Environment, told pv magazine. “The document focuses on the necessity of building specimens in a representative manner and takes into account crucial elements such as the use of anchors or glue, welding of the waterproofing membranes, use of ballast, or other specific elements.”

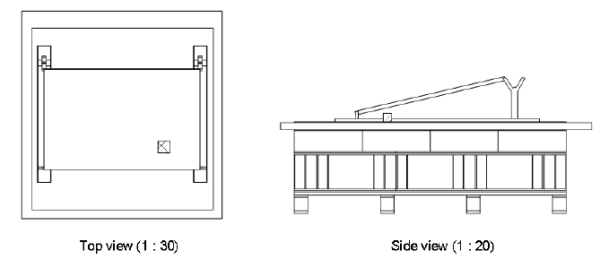

The novel method uses a test deck made of noncombustible materials to support the roof sample with the PV system. Modules must not exceed 1.8 meters by 1.2 meters and can be tested in two configurations. The mid-scale test uses a 2 meter by 2 meter roof, while the large-scale test requires a 4 meter by 4 meter roof. The report must include details on the buildup and the mitigation layer with a roof membrane.

Image: Slovenian National Building and Civil Engineering Institute

“The test method mimics a scenario where a fire starts on the roof membrane below the PV system, thereby representing a failure in the PV electrical components or an external source of fire spreading to that point (flying brands from neighboring buildings, wildfire),” the researchers said. “The ignition source should create enough energy for the fire to propagate outside of the initial area of the ignition source, typically in a period of 10 ± 5 min.”

The fire source consists of a wood crib made from four layers of spruce wooden sticks, with two supporting sticks nailed underneath. This ignition source has a theoretical heat release of 16.56 kW and should be positioned between the roof sample and the PV panel. To aid ignition, isopropyl alcohol should be poured on the wood crib. Forensic testing of the PV and roof materials should begin 150 minutes after the combustion ends, allowing time for the materials to cool.

“Photos of the damage on the PV system (mounting system elements, state of the PV module) and each layer shall be taken,” the researchers explained. “Measurements of damaged material, damaged surface area, burnt material, appeared openings, the size/volume of burnt/melted materials, or its color that is different from the original shall be documented.”

The report should assess various changes, including ignition of other elements, visible changes or deformation of specimen elements, material changes or deformation, enlarged gaps between materials compared to their initial state, damage from additional elements like ballast, anchors, or glue, the fire's spread area, and the extent and depth of material damage.

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd