Miniature field testing shows alpine PV array performs better than expected

Scientists from ZHAW Zurich University of Applied Sciences have tested a miniature of a fully automatic multi-row high-alpine PV array. The miniature was designed as a 1:12 scale of an alpine PV field and was installed at an altitude of around 2,500 m in Davos, Switzerland. It consisted of three rows of seven back-to-back monofacial panels, virtually mimicking bifacial modules.

“High-alpine installations are not commonplace nowadays, and as such, there is not much real-world experience in planning and optimizing the field layouts. Yield calculations in steep terrain, in combination with a highly reflective snow cover, are particularly complex,” corresponding author Michael Wild told pv magazine. “We were able to show that an industry-standard software is capable of performing these calculations to a satisfying degree, although there are a number of factors that have to be paid special attention to, such as the albedo of snow. This should raise confidence in simulation results, which hopefully in turn raises investor confidence.”

The glass-glass PV modules were tailor-made and consisted of three individual interdigitated back-contact (IBC) cells, with dimensions of 90 mm × 43.3 mm each and a maximum power of 2.6 W. Each module row consisted of a carbon fiber rod, onto which the modules were fastened. The whole assembly is fixed to the roof of the shipping container housing the electrical equipment. To keep albedo levels under control, a white aluminum sheet was placed under the modules with an albedo of 0.798, corresponding to fresh snow. Silicon heaters were placed underneath to stop the accumulation of snow and ice.

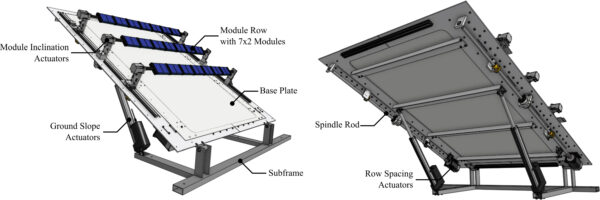

Different motors were able to change the positions of the modules. The whole array was able to change its ground slope from a minimum of 0◦ to a maximum of 40◦; the spacing between the rows was changing between 115 mm to 700 mm, and the inclination of the modules themselves was set in the rage of −40◦ to 90◦. Overall, 80 combinations of positions were tested, focusing on the middle modules of the southern and northern rods.

The testing was carried out from October 2023 to March 2024, with the results from December and January being omitted due to technical errors. To validate the miniature system, the team compared it to a full-size PV system located at the same testing site. It comprises six groups of three to four modules, with mono- and bifacial groups at module inclinations of 40◦, 60◦, and 90◦.

Image: ZHAW Zurich University of Applied Sciences, Solar Energy, CC BY 4.0

“In general, the measurements of both systems are in remarkably good agreement with each other,” the team highlighted. “For the monofacial comparison, deviations of less than 1% were observed in November and February, 3.9% in March, and 14.2% in October. The comparisons of bifacial measurements were slightly more variable but still remarkably close, given the differences in system design.”

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd