Integrating low-temperature heat sources in industrial-scale heat pumps

Researchers from Germany's Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) have proposed a novel method for assessing and comparing low-temperature heat sources for integration with industrial heat pump operations.

The proposed method is based on five steps: Identifying heat sources; evaluating their heat availability and potential; approximating the cost of heat source extraction and supply; comparing the potentials and costs; and finally yielding recommendations to municipal heat planners.

“All local municipal heat sources need to be assessed for their potential and availability,” the group said. “Individually assessing each heat source, including air (ambient and exhaust), water (rivers, lakes, oceans, wastewater), and soil (surface and deep geothermal) will contribute to more informed decision-making for municipal energy planners. In this regard, this paper suggests an indicator-based heat source evaluation method using open-source data.”

The first step uses open-source geographic information tools like Open-StreetMap. This information – which includes industrial sites, wastewater treatment facilities, water wells, and river and lake areas – is collected within a geoinformation system (GIS). However, the team highlights that heat sources like deep geothermal, data centers, mines, and industrial waste heat sites may not be identifiable without detailed research.

The second step includes considering all the different indicators for potential low-temperature heat sources. A total of 40 indicators are considered in technical, regulatory, economic, and environmental categories. Different calculations, based on those indicators, are used to assess the potential of the different air-based, water-based, ground-based, and solar-based heat sources.

The next step is the cost approximation one, which is based on technical potential assessment. “Each identified heat source is evaluated based on the expected investment and operating cost of thermal generation units. The required generation capacity is matched with heat demand close to the location in an area of two-by-two km2 to estimate the possible capacity sizes of heat exchangers, building measurements, heat pumps, control, and other necessary generation components and allocate their cost,” the academics explained.

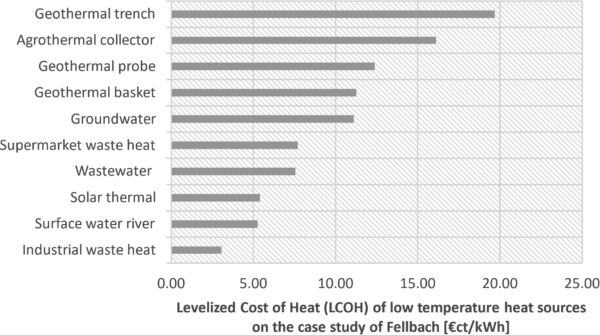

The fourth step of the proposed method compares the results in four frameworks. The first is compression in absolute terms by heat exchanger and source, as yearly energy quantities for the specific analyzed area. The second is a relative comparison when only sources of the same geographical type are compared. The third framework compares the certainty of the heat sources based on a quantitative data quality assessment. The last proposed framework compares the heat sources by the levelized cost of heat (LCOH).

Image: Fraunhofer Institute for Solar Energy Systems (ISE), Applied Energy, CC BY 4.0

“The recommendation in step 5 is based on the previously introduced four steps of the methodology and concludes with a list of promising heat source candidates within the chosen boundaries of the study subject,” the researchers explained. “The recommendation process summarizes the results in a repeatable way for the deciding planners.”

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd