EV uptake helping drive increased demand for green steel

From pv magazine print edition 11/24

As it did with lithium-ion batteries, the automotive sector looks set to become a demand driver and transformational force for a crucial aspect of the global energy transition. Carmakers are emerging as the first large-scale purchasers of green steel. With the automotive industry responsible for 12% of global steel demand, according to the World Steel Association, the scale of this demand is kick-starting efforts by manufacturers to ramp up emission-free manufacturing of this key commodity.

The logic behind automotive demand is clear. As carmakers vie for position in a marketplace in the throes of a rapid transition toward electrification, utilising green steel can strengthen the environmental credentials of the automakers, and may be a key differentiator, particularly for environmentally conscious electric vehicle (EV) buyers. With a cost premium of some 20% to 30%, according to Simon Nicholas, the lead analyst for Global Steel at the Institute for Energy Economics and Financial Analysis (IEEFA), green steel is not prohibitively expensive for many carmakers.

“In terms of the price of a car, considering how much steel is actually in a car, it doesn’t make much difference to the overall price,” said Nicholas. “It does impact the customer but we’re talking hundreds of dollars rather than thousands.”

Increased demand for green steel from automakers is coming at a critical time in the development and adoption of processes required for its production. This demand points to a virtuous circle formed by green steel and renewable energy. Large amounts of renewable energy generation capacity will be required by green steel makers to supply electric furnaces and green hydrogen electrolysers. As the energy transition accelerates, fast-growing solar and wind, plus electricity network expansion will require large amounts of green steel.

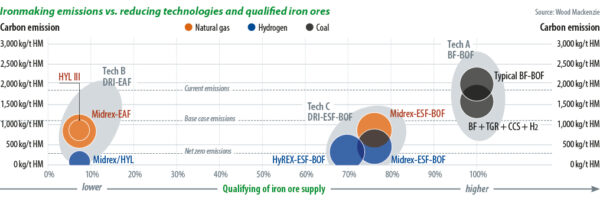

Carbon-intensive processSteel production has been and remains a carbon-emission-intensive endeavor. Steel production is broadly considered to be responsible for anywhere between 8% and 11% of global CO2 emissions. Market intelligence company Wood Mackenzie finds that 3.6 billion tons of CO2 were produced for 1.89 billion tons of crude steel in 2023.

Steel is predominantly produced via two methods, either from integrated blast furnace-basic oxygen furnaces (BF-BOFs) or from electric arc furnaces (EAFs). Blast furnace operators, which account for roughly 70% of global production, make steel from iron ore and use coal as a reducing agent – extracting the iron from the ore and providing the carbon required by steel. The International Energy Agency, observing that the steel industry is not on track to meet its Net Zero Emissions by 2050 (NZE) scenario, describes blast furnace operators as being “highly reliant on coal.”

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd