Controlling water-to-water CO2 heat pump for optimal coefficient of performance

Scientists led by China’s Dongguan University of Technology have proposed a novel control approach for water-to-water heat pumps that uses carbon dioxide (CO2) as refrigerant. The model-based optimal control (MC) was tested against a typical control (TC) mechanism over a virtual heat pump, improving the COE by up to 14.6%.

“An efficient optimization strategy for the MC of water-to-water CO2 heat pump, aiming at reducing computational burden remains undeveloped. Hence, this study aimed to develop an MC for improving the COP of water-to-water CO2 heat pump by identifying optimal variables,” the group said. “System models were derived using extensive data from a virtual CO₂ heat pump whose reliability was validated prior to further simulations.”

The water-to-water CO2 heat pump contained an evaporator (ET), a liquid receiver (LR), an internal heat exchanger (IHX), a compressor (CM), a gas cooler (GC), an expansion valve (EX), and two circulation pumps (PMs). The TC employs fixed setpoints and simple control loops to regulate specific parameters without considering system-wide optimization.

To develop the more refined MC, the team has constructed a virtual CO2 heat pump in MATLAB and REFPROP. 3,969 cases were operated to identify system models, describing how the heat pump responds to changes in operating conditions. An experimental setup was designed to validate the system, showing an average error of 4.4% for the gas cooler outlet temperature and 7.4% for the compressor power.

The scientists analyzed the system components' thermodynamic behavior and developed an optimization algorithm to maximize COE by identifying optimal discharge pressure and gas cooler outlet water temperature setpoints. They tested the system in three case studies for both the MC and TC models.

Image: Dongguan University of Technology, Case Studies in Thermal Engineering, CC BY 4.0

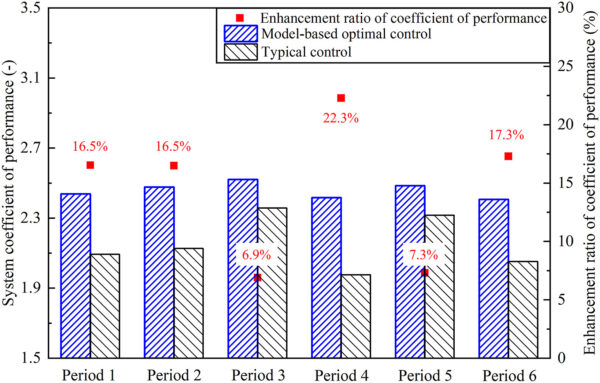

In the first case study, researchers fixed the evaporator mixture inlet temperature at 18 C and randomly set the gas cooler inlet water temperature between 29 C and 35 C. The target outlet temperature at the gas cooler varied between 40 C and 48 C. The MC achieved a 9.9% higher COP than the TC, with an average COP of 2.49 compared to 2.265 for TC.

In the second case study, the gas cooler inlet water temperature was fixed at 32 C, while the evaporator mixture inlet temperature ranged from 17 C to 19 C. The target outlet temperature at the gas cooler was randomly varied between 40 C and 48 C. The MC outperformed the TC by 8%, with an average COP of 2.482 compared to 2.3 for TC.

In the final case study, the evaporator mixture inlet temperature ranged from 17 C to 19 C, the gas cooler inlet water temperature varied between 29 C and 35 C, and the outlet water temperature at the gas cooler ranged from 40 C to 48 C. The MC achieved a 14.6% higher efficiency, with an average COP of 2.458 compared to 2.145 for TC.

“The computational time of the system with multiplexed optimization strategy was reduced by 42.2% to 47.1% compared to traditional optimization strategy,” the team said. “These results indicated that the formulated MC could effectively enhance the energy efficiency of the water-to-water CO2 heat pump. The developed multiplexed optimization strategy effectively reduced the computational burden and slightly decreased the average COPs. Thus, this study provided a guideline for implementing MC in water-to-water CO2 heat pumps, contributing to COPs enhancement.”

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd