Balcony PV systems for cruise ships

A research group led by scientists from the German Aerospace Center (DLR) has simulated the installment of PV modules on cruise ship cabins to power their utilities.

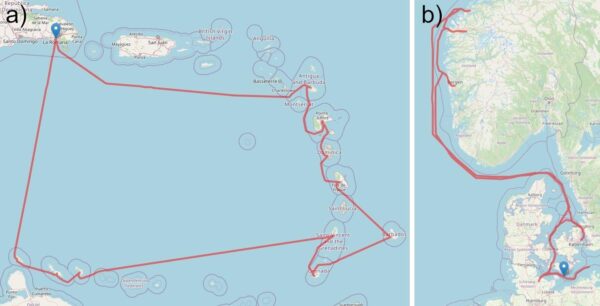

As the cruise industry is transferring to direct current (DC) onboard grids, the team has suggested three approaches to PV integration, comparing them for efficiency. To find the ideal approach, they simulated cruises in the Caribbean and along the Norwegian and Danish coasts and presented the system’s performances.

“This article presents a realistic photovoltaic system for a cruise ship, with potential for optimization. Additionally, it proposes a subdivision of the PV system and at the voltage level at which it can be connected,” they said. “The concept will be further developed with the introduction of a battery storage system, specifically designed for this area of application. This system will assume both system-serving and safety-related tasks.”

In their proposal, two 250 W and 22%-efficient panels are installed at each cabin balcony – one is integrated into the glass barrier of the balcony at an angle of 90◦; the other is affixed at an angle of 30◦, under the balcony and between the decks. For scale, a Helios class cruise ship has 1,655 balcony cabins and would, therefore, have a maximum output of 827.5 kW.

Image: DLR Institute of Networked Energy Systems, International Journal of Electrical Power & Energy Systems, CC BY 4.0

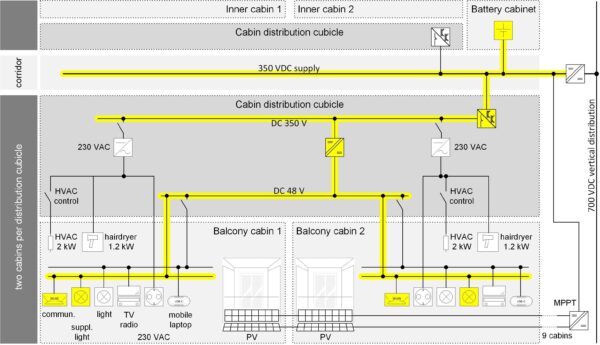

“The assumed low voltage DC distribution grid is based on two voltage levels, 700 V and 350 V. The 700 V grid, starting from the engine room, is considered the main low voltage distribution and providing power to all fire zones on the ship,” the academics explained. “A fire zone is defined as an area that can be isolated from other areas by means of automatic fire bulkheads. The power distribution for each deck within a fire zone, consisting of nine starboard, nine port, and 18 interior cabins, is unidirectional and has a lower voltage level of 350 V. The cabins are powered by a 48 V network, which is fed from the 350 V distribution network.”

Based on those characteristics, the group has suggested three designs: in the first, the solar modules are directly connected to the 48 V cabin grid; in the second, they are connected to the 350 V distribution network; and in the last, they are paired to the primary 700 V grid. Comparing all the proposals, the team found that the third design has a conversion loss of 2% to 3% greater than the two other systems. The cabin grid suggestion was the safest, but also with the highest cost and maintenance efforts. As the 350 V distribution network was safer than the 700 V grid proposal and cheaper and with less maintenance than the cabin room system, it was chosen as the ideal one for the simulation task.

A series of simulations were conducted to determine the optimal size of the battery and only one deck of a fire zone was considered for the simulation.

“The battery is used to provide emergency power and to buffer peak loads in the 36 cabins during normal operation,” the team said. “Given that 18 interior cabins must be supplied by the PV systems of the 18 outside cabins, it cannot be assumed that the energy output will be sufficient. It is, therefore, essential to connect to the 700 V grid. Consequently, the battery should be sufficiently large to ensure a constant flow of energy from 700 V to the 350 V grid.”

Image: DLR Institute of Networked Energy Systems, International Journal of Electrical Power & Energy Systems, CC BY 4.0

Customized/OEM/ODM Service

HomSolar Supports Lifepo4 battery pack customization/OEM/ODM service, welcome to contact us and tell us your needs.

HomSolar: Your One-stop LiFePO4 Battery Pack & ESS Solution Manufacturer

Our line of LiFePO4 (LFP) batteries offer a solution to demanding applications that require a lighter weight, longer life, and higher capacity battery. Features include advanced battery management systems (BMS), Bluetooth® communication and active intelligent monitoring.

Customised Lithium Iron Phosphate Battery Casing

ABS plastic housing, aluminium housing, stainless steel housing and iron housing are available, and can also be designed and customised according to your needs.

HomSolar Smart BMS

Intelligent Battery Management System for HomSolar Energy Storage System. Bluetooth, temperature sensor, LCD display, CAN interface, UART interface also available.

Terminals & Plugs Can Be Customized

A wide range of terminals and plugs can be customised to suit the application needs of your battery products.

Well-designed Solutions for Energy Storage Systems

We will design the perfect energy storage system solution according to your needs, so that you can easily solve the specific industry applications of battery products.

About Our Battery Cells

Our energy storage system products use brand new grade A LiFePO4 cells with a battery lifespan of more than 4,000 charge/discharge cycles.

Applications in Different Industries

We supply customized & OEM battery pack, assemble cells with wiring, fuse and plastic cover, all the cell wires connected to PCB plug or built BMS.

Applications: E-bike, Electric Scooter, Golf Carts, RV, Electric Wheelchair, Electric Tools, Robot Cleaner, Robot Sweeper, Solar Energy Storage System, Emergency Light, Solar Power Light, Medical Equipment, UPS Backup Power Supply.

We can provide you with customized services. We have the ability to provide a vertical supply chain, from single cells to pack/module and to a complete power solution with BMS, etc.

HomSolar (Shenzhen) Technology Co., Ltd